What is Reorder Point? Reorder Point Definition html5-dom-document-internal-entity1-amp-end Formula

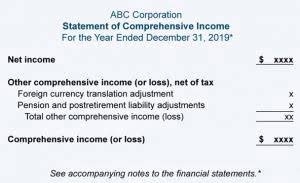

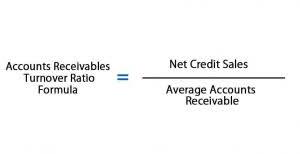

To determine the demand during lead time, you’ll need to figure out your company’s average daily sales first. Average daily sales are your total sales divided by a number of set days. The lead time is the number of days between when you place an order with a manufacturer and when your company receives that order. Demand during lead time is determined by multiplying the lead time, usually in days, by the average daily sales number you just determined. The calculation consists of an item’s delivery time, demand or consumption rate, and, if applicable, its safety stock level. Since all of these are dynamic variables, the ROP of an item can vary greatly depending on changes in the supply chain, market circumstances, selected suppliers, etc.

- Simply stated, the goal of inventory management is to have the right amount of inventory in the right place at the right time.

- Managing inventory is an essential aspect of many businesses, and knowing when to reorder stock can make the difference between a seamless operation and costly interruptions.

- Sales volume is another important factor to consider as it pertains to setting safety stock for reorder point calculations.

- Once you have these two important metrics – demand during lead time and safety stock – you can revisit the reorder point formula to determine when you’ll need to replenish inventory.

- The your vendor takes to supply the items, the more sales you’ll be losing.

How to Calculate Reorder Point

Keeping optimal stock levels in order to avoid stockouts is an integral task of inventory management. One of the most fundamental ways in which to ensure this is setting and maintaining the right reorder points. The reorder point calculator is a tool that helps you determine the perfect time to reorder inventory. Safety stock is a term used in inventory management that refers to a level of extra stock that is maintained to mitigate the risk of stockouts. Stockouts can lead to lost sales, unhappy customers, and production delays, so it is important to have a safety stock buffer to protect against them.

Optimize stock control with Zoho Inventory

- Negative reviews can quickly erode any positive online presence you’ve built.

- This ensures you know which products are running low on stock and have enough lead time to replenish inventory before quantities reach zero.

- Remember, the goal of setting safety stock is to strike a balance between the cost of carrying extra inventory and the risk of stock outs.

- To capture safety stock, you can input “buffer days,” which are additional days factored in with a vendor’s lead time to increase the number of units ordered.

“Setting a reorder point is a simple but effective way to keep inventory at a safe level. With a carefully determined reorder point, retailers can not only lower the risk of stockout, but also reduce inventory holding costs,” Miao says. This formula considers costs related to setup, production, and storage, as well as other factors that include demand.

- In other words, if you want to run an efficient business, you can’t rely on intuition to determine when to reorder stock.

- The EOQ is the point at which the company’s ordering and carrying costs are equal.

- Knowing your business, including target, risk, and cost, is the first and necessary step to setting reorder points.

- Once you have calculated the safety stock and demand during the lead time, you simply have to put these values in the ROP formula and your ROP is ready.

- You are being directed to ZacksTrade, a division of LBMZ Securities and licensed broker-dealer.

- If you’re a business owner, knowing when to order more stock is important.

Difference between Stock Replenish vs reorder point?

Lead what is rop in business time in this context refers to the time required to receive fresh supplies from the supplier. An accurate reorder point for each product will ensure that you always have enough stock to meet the consumer demand without using excess capital resources. When you decide on a safety stock level, you’ll want to consider average daily sales and the daily average you use the product in work orders (if applicable).

Reorder point benefits for efficient inventory management

By understanding your sales rate, you can more accurately forecast future demand and ensure you have the inventory on hand to meet customer needs. The goal is to find the perfect balance of inventory levels so that you have enough stock to meet customer demand without tying up too much capital in inventory. Understanding https://www.bookstime.com/articles/liability-accounts and using reorder point is essential to maintain optimized inventory levels.

In a report released on October 16, Jefferies also maintained a Buy rating on the stock with a $635.00 price target. Given the wide variety of products involved, as well as their complexity, firms will often employ multiple ROPs. In some cases, one person is designated as the principal while another is designated as the alternate ROP. These positions are often reserved for senior members of the firm, such as its partners, officers, or directors.

Company

Our experts picked 7 Zacks Rank #1 Strong Buy stocks with the best chance to skyrocket within the next days. Before a company reveals its earnings, it is vital to take into account any changes in earnings projections. These revisions play a pivotal role in predicting the possible reactions of investors toward the stock. Multiple empirical studies have consistently shown a strong association between trends https://x.com/BooksTimeInc in earnings estimates and the short-term price movements of a stock.

Typically, when you don’t have safety stock, your reorder level and the frequency of your orders tend to be higher. As we explained, you determine reorder points by multiplying your daily sales velocity by shipment lead time, and adding in any safety stock. If you notice a change in sales velocity or lead time, it’s time to set new reorder points. Knowing the reorder point and following it as part of your company’s inventory management can help strike that perfect balance between having too much inventory and too little inventory.